Grinding wheel dynamic balance unit can be realized balance by moving the counterbalance which installed in the spindle, manual or automatic mode are available.

The standard grinding wheel dressing unit is located at the one side of the tailstock, or located at a separated stand under the special conditions, special grinding wheel dressing unit can be used for radial dressing or end face dressing.

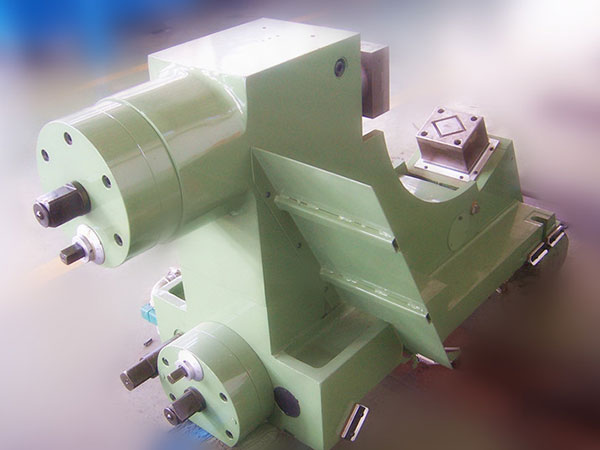

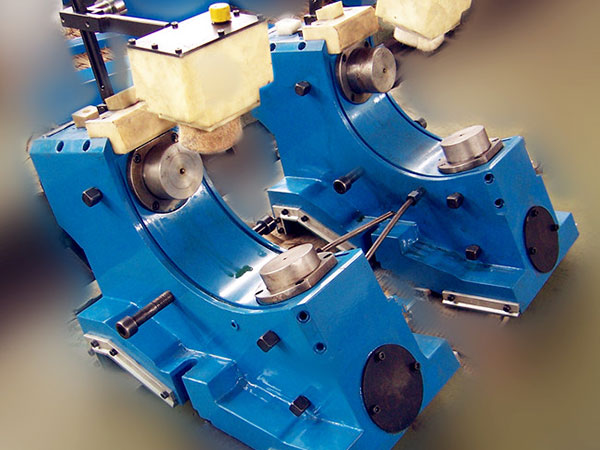

The roll supporting shoe must be strong and firm to avoid any possibility of vibration. The roll start must be quickly, and also easy to change. In order to meet these demands, SY series products provided normal supporting shoe, auto-adjustable supporting shoe, grinding supporting shoe with bearing housing, as well as the supporting shoes with roll soft landing unit, roll auto-balancing and correction.

bracket

bracket bracket

bracketThe Roll Grinding Machine should be fixed on the wedge, for the purpose of adjustment in vertical and horizontal direction as well as re-correction in the future, also it is possible to put the whole grinding machine on an anti-vibration foundation, to prevent the influence of roughness on the roll surface by vibration.

There are many kinds of filtering system available for the Roll Grinding Machine, it can be selected according the customers’ requirements.

The main oil supply is constant-temperature controlled, thus enable the spindle film rigidity even more strong and steady.

Oil supply system and temperature control system.

Oil supply system and temperature control system. Static balance frame

Static balance frameIt is also available to provide full set of dust collecting, filtering and discharging system as well as fume extractor for dry grinding operation.

Roughmeter, defectoscope or hardometer are available for auto-measuring and recording output.

Coolant filter system.

Coolant filter system. Coolant filter system.

Coolant filter system.